Aircraft Wiring Harness Market: Powering the Future of Avionics and Aircraft Performance

The aircraft wiring harness market plays a pivotal role in the modern aviation ecosystem by ensuring efficient power distribution, signal transmission, and overall system functionality within aircraft. As aircraft systems become increasingly complex with digital cockpits, in-flight entertainment, and fly-by-wire technologies, the demand for advanced wiring harness solutions continues to soar.

Market Overview

The aircraft wiring harness market has witnessed steady growth in recent years, and the trend is expected to continue with the surge in both commercial and military aircraft production. According to recent industry insights, the market is projected to reach US$ XX billion by 2031, growing at a CAGR of XX% from 2023 to 2031. The growth is fueled by increasing passenger traffic, technological advancements in aircraft design, and growing defense expenditure.

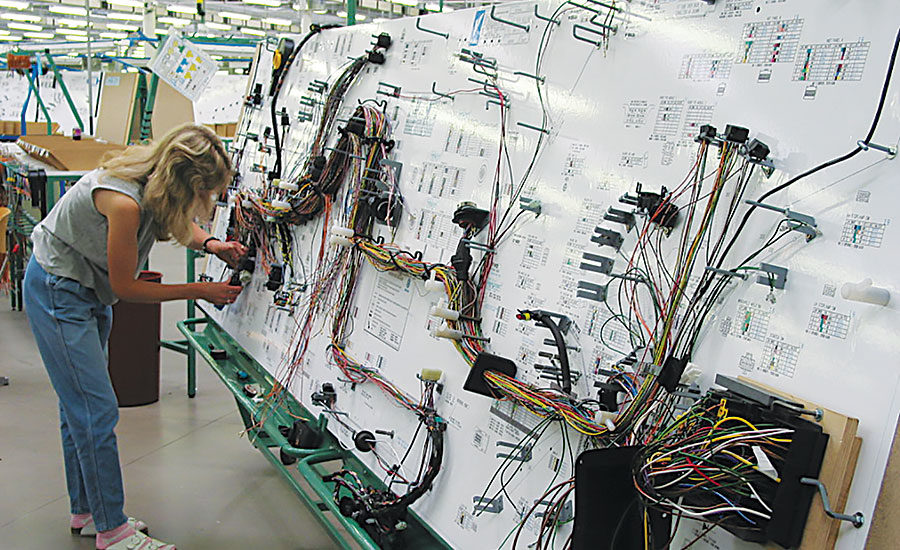

Aircraft wiring harnesses serve as the backbone for the electrical systems of an aircraft, interconnecting a wide array of electronic components such as sensors, actuators, power systems, and communication devices. These harnesses must withstand extreme environmental conditions, including vibration, Thermoplastic Elastomers temperature fluctuations, and electromagnetic interference, making their design and material selection critical.

Key Drivers of Market Growth

- Growth in Commercial Aviation: The rapid expansion of low-cost carriers and increasing global connectivity have driven demand for new aircraft, boosting the aircraft wiring harness market.

- Technological Advancements:Innovations such as fiber-optic wiring, lightweight materials, and smart harness technologies are revolutionizing the aircraft wiring harness landscape.

- Military Modernization:Defense agencies across the globe are investing in upgrading aircraft fleets, which directly translates into a higher need for robust wiring harness systems.

- Increasing Demand for Lightweight Components:Airlines aim to improve fuel efficiency and reduce carbon emissions. Lightweight wiring harnesses significantly contribute to this goal by minimizing overall aircraft weight.

- Integration of Avionics and Automation: As cockpit and cabin systems become more digitally integrated, wiring complexity increases, leading to a rise in the use of advanced wiring harnesses.

Market Segmentation

The aircraft wiring harness market is segmented based on:

- Type: Shielded and unshielded wiring harnesses

- Material: Thermoplastic and thermoset

- Application: Avionics, lighting, propulsion, cabin interiors, flight control systems

- Aircraft Type: Commercial, military, and business jets

- End-User: OEM and aftermarket

Each segment plays a crucial role in determining the overall dynamics of the aircraft wiring harness market. For instance, the OEM segment dominates the market, as new aircraft production inherently requires a full suite of custom wiring harnesses.

Emerging Trends

- 1. Lightweight and High-Durability Materials: New-generation aircraft wiring harnesses are increasingly manufactured using materials like polyimide and PTFE, which offer superior heat resistance and flexibility while reducing weight.

- 2. Smart Wiring Harness Systems: With the advent of IoT and predictive maintenance technologies, smart wiring harnesses are being integrated with sensors to monitor performance, reduce downtime, and enhance safety.

- 3. Fiber Optic Cabling: To support high-bandwidth applications such as in-flight connectivity and advanced navigation systems, manufacturers are exploring fiber optic wiring harnesses for faster and more efficient data transmission.

Challenges and Constraints

Despite the promising outlook, the aircraft wiring harness market faces certain challenges:

- High Production Costs:The use of specialized materials and stringent aerospace certifications can make production costly.

- Complex Manufacturing Process:The intricate design and assembly of wiring harnesses require skilled labor and advanced manufacturing capabilities.

- Stringent Regulatory Environment:Compliance with aviation standards like FAA and EASA adds to the complexity and cost of product development.

Regional Insights

- North America leads the global aircraft wiring harness market, driven by the presence of major aircraft manufacturers and defense contractors.

- Asia-Pacificis emerging as a high-growth region due to increasing aircraft deliveries and expanding aerospace manufacturing capabilities, particularly in countries like China and India.

- Europe maintains a strong position with robust R&D investments and collaborations among aviation giants.

Conclusion

The aircraft wiring harness market is on a strong upward trajectory, bolstered by technological innovation, rising aircraft deliveries, and a growing emphasis on lightweight and efficient electrical systems. As the aviation industry embraces digital transformation, the demand for intelligent and robust wiring solutions will only intensify. For manufacturers and stakeholders, staying ahead of the curve with innovation and compliance is key to unlocking the full potential of this high-growth market.

Comments

Post a Comment